First Day (4-25) of Building

On the first day of building, the wooden platform and acrylic were cut. A hole was then drilled through the wooden platform. Two pulleys and a rod were also 3D printed. The container was waterproofed using plastic wrap, tape, the acrylic, and hot glue. The straw system was created using hot glue and tape. A hole was then drilled through the end of the mop handle and the top of the mop handle. One pulley was attached to the rod using a tape stopper and hot glue. The rod was then run through the bottom hole such that it could freely spin. The second pulley was then attached in the same format as the first. The hook was then attached to the top hole using hot glue.

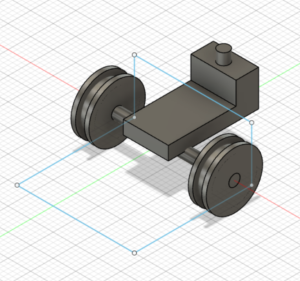

Pulley Simulation

Second Day (4-26) of Building

On the second day of building, the wooden platform was sanded and shaped into a rounded format. The straw system was also attached to the container using hot glue and a tape stopper. The support brick was then cut and attached using hot glue. The wooden platform and spray nozzle were also attached using hot glue. The container was then attached to the wooden platform. The string was then measured, cut and tied into a circle and attached at the bottom to the spray nozzle and wrapped around the hook at the top.

Final Prototype Spray System Photo

Third Day (4/28) of Building

On the third day of building, the bottom of the mop handle was sanded and the mop head was attached using hot glue and tape. The prototype was then brought to the user for testing.